US Add:Orkan18.LLC.9284 talway cir Boynton

beach.fL33472

Tel:+001-8556752618

Mobile:(001)5613126473

Cel:+86-158-1188-2441

Phone: +86-755-25423447

Fax: +86-755-25417648

Email: jackdu999@yahoo.com

Semi auto ultrasonic tube sealer Plastic laminated cosmetic cream tubes soft tube sealing equipment

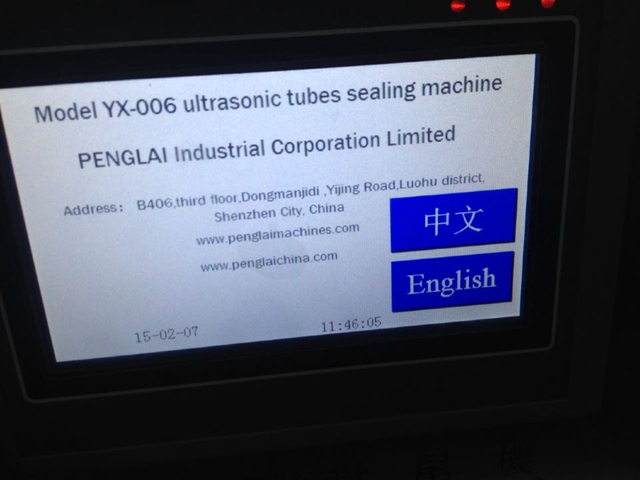

Published by:PENGLAI INDUSTRIAL CORP LTD

Cel:+86-15811882441 +86-13077872898

Phone:+86-20-84206097 +86-755-25423447

Email:jackdu999@yahoo.com

Email:penglaipacking@gmail.com

►1. Machine functions & applications

►2. Model YX-006 main features

Ultrasonic tube sealer functions and applications Model YX-006

Using ultrasonic to weld plastic soft tube tail. It doesn't need any adhesive or filler or solvent when welding, do not consume large amounts of heat, and easy to operate, high welding speed, high efficiency.

PENGLAI brand model YX-006 Semi automatic ultrasonic tube sealer mainly use for toothpaste, food, cosmetics, pharmaceutical, chemical, and other plastic, PE, aluminum laminated tube sealing.

Soft tube sealing machine Main features:

1. Adapts ultrasonic sealing technology,no need warm-up time,more stable and neat sealing, no distortion, and a low reject rate of less than 1%.

2. Manual feed the tube,press start button,the machine could automatically identify the registration mark, sealing( with coding), end trimming.

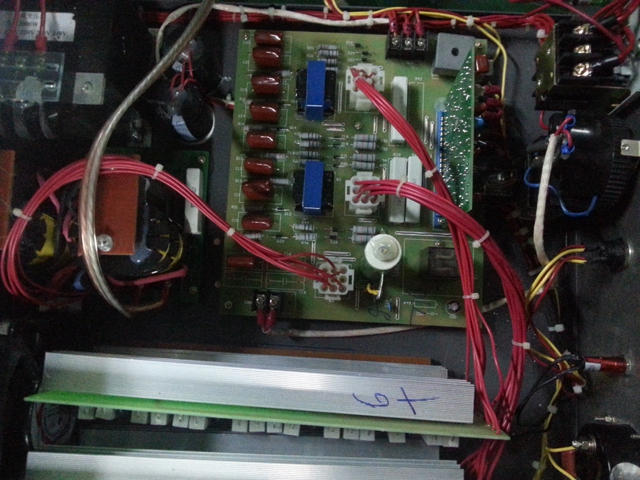

3. Independent R&D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency,

with power auto compensation function, avoiding the reduction of power after long time use.Could freely adjust the power based on tube material and size, stable and minimum the fault rate,

extend the life span than the normal electrical Electrical box.

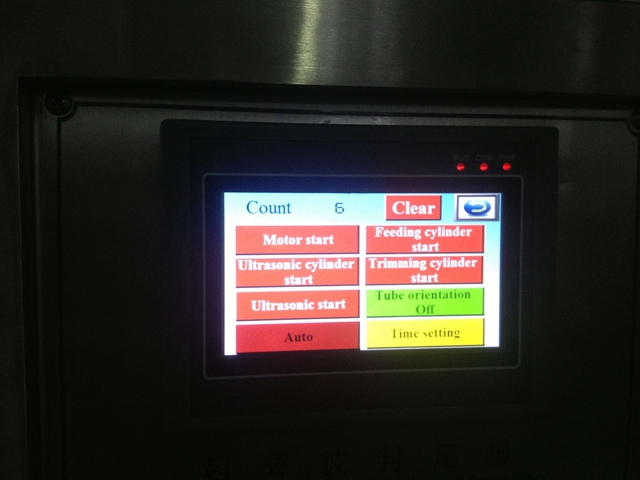

4. PLC with touch screen control system, providing a friendly operation experience.

5. Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

6. “Panasonic” high sensitive sensor with stepping motor, could track the registration mark precisely.

7. Tabletop design, practical and compact.

Product parameter of Model YX-006 semi auto single head ultrasonic tube sealer

Model YX-006

Frequency:20kHz

Power:2600w

Power supply:AC220V/110V 1PH 50/60HZ

Speed: 8-12pcs/min

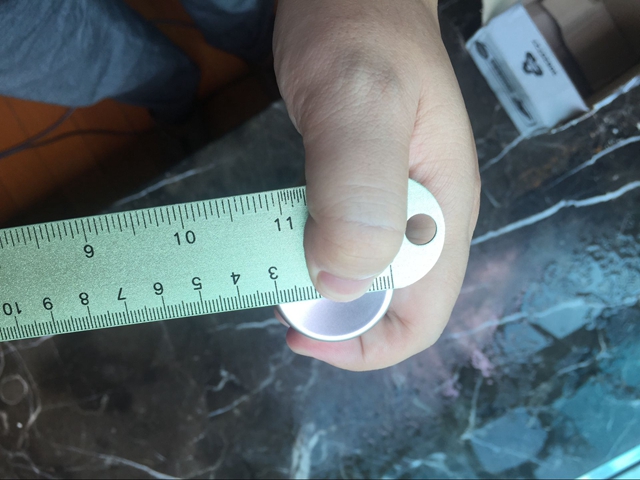

Sealing diameter: 10-50mm

Tube height: 10-250mm

Air pressure: 0.6Mpa

Dimension: L 850*W 600* 730mm

N.W: 85kgs

*Note: The above parameters are for reference only. The machine constantly upgrades parameters that may cause the actual discrepancies, please understand.

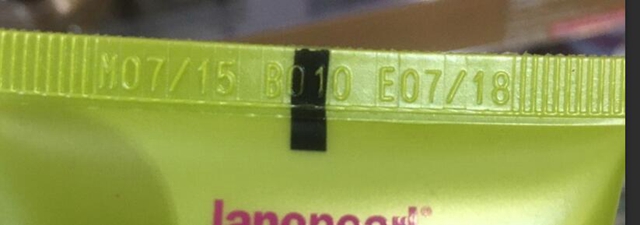

Optional choice: Date coding

Chaging parts: Tube holder (Custom made according to tube size)

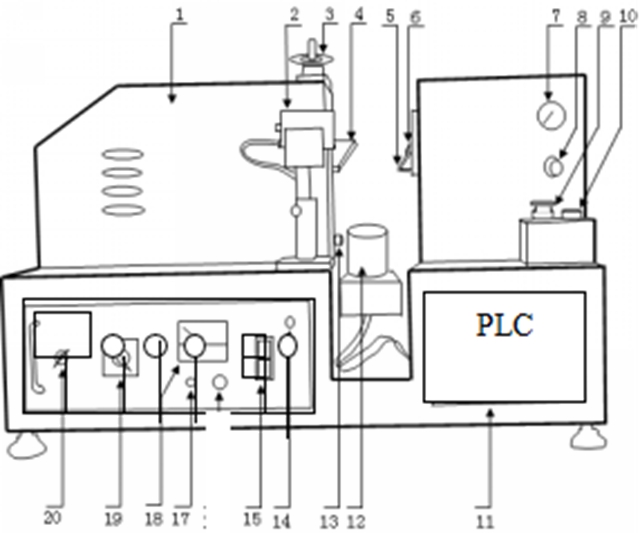

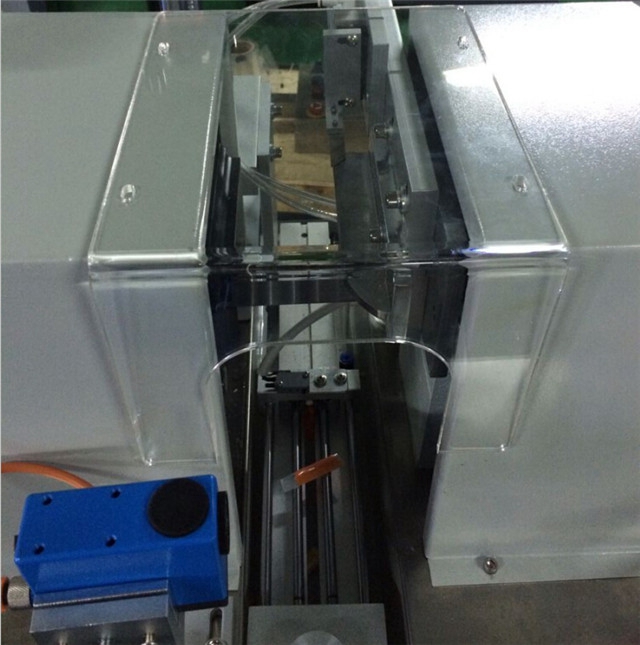

Plastic tube sealing equipment main parts

1. Main body 2.Sensor 3.Tube Hight adjustment 4.Front mould 5.Back mould 6.Cutter

7. Gas-pressure meter 8.Gas-pressure adjustment 9.Emergency button 10.Start button

11.PLC 12.Holder 13.Moulds gap adjustment 14.Power lamp 15.Power switch 17.Tune 18. OSC check 19.Over load lamp 20.Loading meter

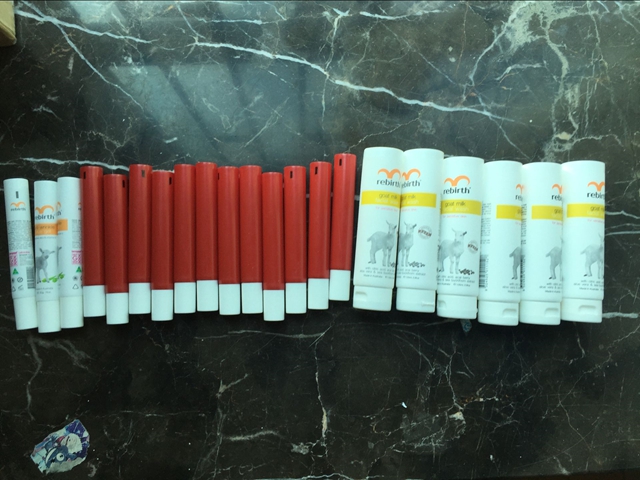

Tubes samples sent from the customers:

Model YX-006 semi auto tube sealer operation process

1. Connect power and compressed air correctly (suggest 0.5MPa).

2. Press the Power switch

3. Press ‘OSC check’ button and set ‘Tune button’ at the same time, Pls using the screw on the Tune button,

you can turn to Left or Right, while find the minimum of ‘Signal light’ (it will about low than 1A) fixed ‘Frequency adjustment’. (do not press ‘OSC check’ continuously, press it intermittently)

4. Put tube on the holder.

5. Press ‘Ultrasonic cylinder start’, front mould and back mould will be closed. set ‘Moulds gap adjustment’, let two moulds just touch and no gap. Press ‘Cutter controller’ and confirm the cutter will

work smoothly.(need to put the plastic tube on the tube holder when you adjusting)

6. Set front mould and back mould and cutter at original position.

7. Put tube on the ‘Holder’ and press ‘Feeding cylinder start’, the tube will run between two moulds. Adjust the height of holder if necessary. (suggest tube is higher than back mould 2 to 3 mm)

8. Make tube back to original position.

9. Set to auto status, turn on sensor if tube has color code otherwise turn off it.

10. Press ‘Auto’ the machine will work automatically.

Remark: Pls also read the machine install video for reference !!!!

Other ultrasonic sealer detailed photos semi auto equipment

Wooden packing before shipment

After-sales service on PENGLAI-brand Machines

Guarantee: for all the machines, it claims one year for guarantee. (Excluded from the warranty are problems due to accidents, misuse, misapplication, storage damage,

negligence, or modification to the Equipment or its components.

ALSO, THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

-

Semi auto ultrasonic tube sealer Plastic laminated cosmetic Semi automatic ultrasonic sealing machine....

Semi auto ultrasonic tube sealer Plastic laminated cosmetic Semi automatic ultrasonic sealing machine.... -

Tubes tail cutting sealing machine ultrasonic sealer equipme Tubes tail cutting sealing machine ultrasonic sealer equipment semi automatic for plastic &laminated tubes...

Tubes tail cutting sealing machine ultrasonic sealer equipme Tubes tail cutting sealing machine ultrasonic sealer equipment semi automatic for plastic &laminated tubes... -

tabletop ultrasound sealing machine semi automatic for plast ...

tabletop ultrasound sealing machine semi automatic for plast ...

ENGLISH

ENGLISH