US Add£ºOrkan18.LLC.9284 talway cir Boynton

¡¡¡¡¡¡¡¡¡¡beach.fL33472

Tel£º+001-8556752618

Mobile£º(001)5613126473

Cel£º+86-158-1188-2441

Phone: +86-755-25423447

Fax: +86-755-25417648

Email: jackdu999@yahoo.com

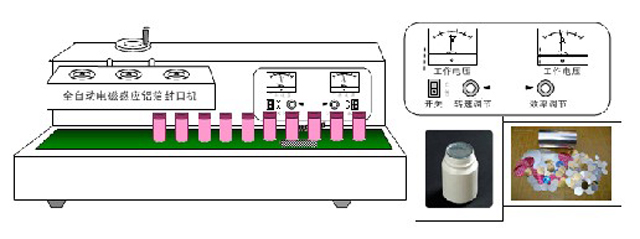

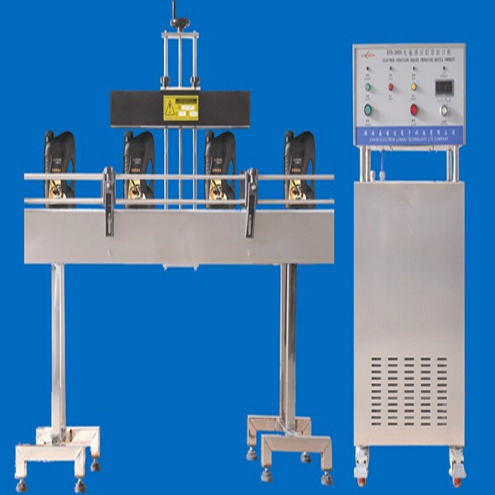

Desktop induction sealing machine electromagnetic aluminum foil wads sealer equipment semi automatic for jars bottles container

Published by:PENGLAI INDUSTRIAL CORP LTD

Cel:+86-15811882441 +86-13077872898

Phone:+86-20-84206097 +86-755-25423447

Email£ºjackdu999@yahoo.com

Email£ºpenglaipacking@gmail.com

Large jars sealing machine tabletop electromagnetic sealer equipment

The continuous-type completely automatic aluminum foil sealing machine ,Horizontal continuous windy cool inductionsealing machine, for plastic bottles with PP,PE,PS,PET,ABS materials,is uses the electromagnetic induction the principle, instantaneous has the high temperature in the bottle mouth aluminum tinsel, then causes the aluminum tinsel fusion in the bottle mouth, enables it to achieve the seal the function. Has moisture-proof, the mold proofing, the forgery-proof function good, thus extension goods retention time. this equipment mainly uses in the assembly line, can the continuous working 24 hours.

|

Model |

YX-S1500A |

YX-S2000A |

|

Voltage |

AC220V±10% 50Hz |

|

|

Power |

1500w |

1800W |

|

Working Current |

≤8 ( A ) |

≤9 ( A ) |

|

Control Circuit |

transistor control circuit |

|

|

Sealing Diameter |

20-50mm |

50-130mm |

|

Bottle Height |

40-400mm |

40-300mm |

|

Working Mode |

Continuous work |

|

|

Cooling Method |

Fan cooling |

|

|

Machine Type |

Desktop Mode |

|

|

Machine Body |

Cold roller sheet/ Stainless Steel+ Aluminum |

Cold roller sheet |

|

Sealing Speed |

0-10m/min |

0-12m/min |

|

External Dimension (L*W*H) |

1150×480×400 ( mm ) |

1150*560*400mm |

|

Net Weight |

38KG |

42kg |

Working Principle

The induction sealing technology which was thought to be very mysterious is actually not very hard to understand. Induction power passes the electric energy to the aluminium foil inside of the cap by induction current. The electric energy translates into thermal energy which melts the polymer pasted on aluminium foil.

So induction sealing is an untouched heat treatment process. The sealing is after filling and capping work.

The FDA considers the induction sealing can effectively keep the trace of opening.

Induction Sealing Machine Components

The continuous induction sealing machine is composed of 3 parts: induction power,

induction sealing head and conveyor.

Power is running in high frequency as a generator, providing electric current for the induction sealing head.

There's induction coil inside the induction sealing head and a stable magnetic field will from around the sealing head

after turning on the machine. The conveyor carries the bottles to the magnetic field

under the sealing head to form a whirlpool on the aluminium foil which translates the electric energy to heat.

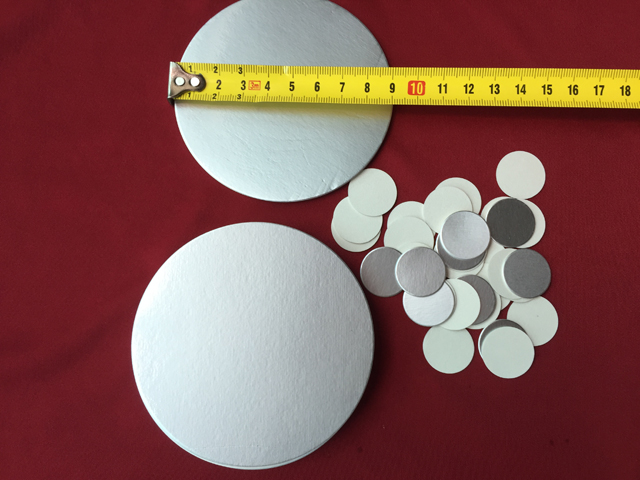

- A layer of pulp board

- A layer of wax

- Aluminium foil

- A layer of polymer (Heat sealable film)

ENGLISH

ENGLISH