US Add£ºOrkan18.LLC.9284 talway cir Boynton

¡¡¡¡¡¡¡¡¡¡beach.fL33472

Tel£º+001-8556752618

Mobile£º(001)5613126473

Cel£º+86-158-1188-2441

Phone: +86-755-25423447

Fax: +86-755-25417648

Email: jackdu999@yahoo.com

hot melt adhesive sealing machine automatic linear type boxes sealer continuous type closing equipment

Published by:PENGLAI INDUSTRIAL CORP LTD

Cel:+86-15811882441 +86-13077872898

Phone:+86-20-84206097 +86-755-25423447

Email£ºjackdu999@yahoo.com

Email£ºpenglaipacking@gmail.com

Hot-melt glue box sealing machine is one of the series of hot-melt glue packaging equipment. It is suitable for carton packaging of food, medicine, sanitary products, toys, electronics, hardware products and other products. It has the advantages of environmental protection, anti-counterfeiting and high efficiency.

Hot melt adhesive (HMA), also known as hot glue, is a form of thermoplastic adhesive that is commonly sold as solid cylindrical sticks of various diameters designed to be applied using a hot glue gun. The gun uses a continuous-duty heating element to melt the plastic glue, which the user pushes through the gun either with a mechanical trigger mechanism on the gun, or with direct finger pressure. The glue squeezed out of the heated nozzle is initially hot enough to burn and even blister skin. The glue is sticky when hot, and solidifies in a few seconds to one minute. Hot melt adhesives can also be applied by dipping or spraying, and are popular with hobbyists and crafters both for affixing and as an inexpensive alternative to resin casting.

In industrial use, hot melt adhesives provide several advantages over solvent-based adhesives. Volatile organic compounds are reduced or eliminated, and the drying or curing step is eliminated. Hot melt adhesives have long shelf life and usually can be disposed of without special precautions. Some of the disadvantages involve thermal load of the substrate, limiting use to substrates not sensitive to higher temperatures, and loss of bond strength at higher temperatures, up to complete melting of the adhesive. This can be reduced by using a reactive adhesive that after solidifying undergoes further curing e.g., by moisture (e.g., reactive urethanes and silicones), or is cured by ultraviolet radiation. Some HMAs may not be resistant to chemical attacks and weathering. HMAs do not lose thickness during solidifying; solvent-based adhesives may lose up to 50–70% of layer thickness during drying.

Hot melt adhesive machine is a comprehensive box which is without the hassle of a glue gun. This machine helps to improve the standard of productivity and overcome waste. It is a faster, efficient and the safest option rather than using a glue gun. It is manufactured to make packaging, assembly, binding and other tasks in no time. Hot melt glue machine safe almost 50% of the glueing costs because it does not waste the glue.

The hot-melt glue box sealing machine series are eco-friendly products newly developed and launched under the strategic concept of "sustainable development", which replaces traditional packaging such as strapping tape and adhesive tape as a carton sealing device. This series of products use degradable non-polluting hot melt adhesive as the adhesive. On the basis of environmental protection, it has high bonding strength and good box sealing effect, avoiding the phenomenon of unpacking tape packaging during transportation; the overall strength of the carton after packaging Strengthen, reduce the deformation and damage rate of the carton; meet the export packaging requirements; disposable packaging, after the carton is opened, it cannot be recovered and recycled, so as to ensure the original product to the greatest extent and prevent you from the trouble caused by counterfeit products. Hot-melt adhesive box sealing is a new type of environmentally friendly packaging on the market. It can replace traditional adhesive packaging and tape packaging. The currently developed models are: semi-automatic box sealing machine, fully automatic glue-spraying box sealing machine, and fully automatic Cartoning and sealing machines, etc., are widely used in packaging and color printing enterprises across the country. It solves a major problem of high labor costs in many factories and low efficiency.

Features of Hot Melt Sealing Box Series

1. The design of continuous three-shift work, the machine can work continuously; ¡¡

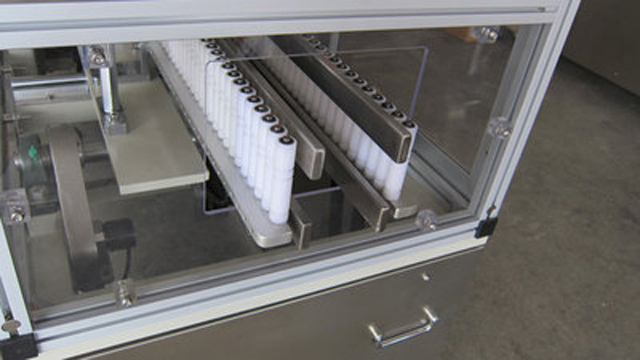

2. Blue acrylic safety door, safe and reliable.

3. No need to change accessories, suitable for color boxes of different specifications and sizes.

4. It can be adjusted to a color box of another specification within 2 minutes.

5. The hot melt glue spray system is controlled by a digital temperature controller.

6. The frequency conversion stepless speed regulation control can control the speed of the box at will.

7. The whole machine has time control, which can control the glue melting in the glue spraying system in advance

Due to the high requirements of packaging equipment in special industries, a hot-melt adhesive box sealing machine with an all-stainless steel structure must be used. The all-stainless steel hot-melt glue box sealing machine is a fully mechanical structure, simple operation and convenient adjustment. It is the first choice for food factories and toy factories for frequent changes of various specifications.

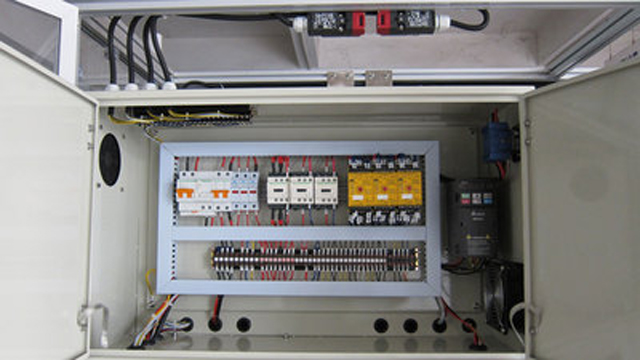

All stainless steel hot melt glue box sealing machine adopts imported PLC control, transparent protective window, and collision protection device to ensure the safety of the operator, not to be scalded, and also to protect the product from being damaged. Expensive toy box sealing is most suitable. .

Because the stainless steel box sealing machine uses imported components and exquisite workmanship, the machine has a very low failure rate and a long service life, up to 20 years.

Basic parameters of hot melt glue sealer Model YX-HS200 Sealer with hot melt adhesive device

Total Weight ≈400KG Total Length ≈4200MM

Total Width ≈700MM Total Height≈1850mm

Box length of finished products100~300MM

Box width of finished products 30~250MM

Box height of finished products 30~180MM

Quantity per minute 1~120pcs

Power voltage 220V 50Hz

Pressure of cylinder 0.2~0.63Mp

Details of hot melt glue device sealing boxes machine:

Boxes samples for hot melt sealer:

Instructions for how to operate the automatic hot melt glue boxes sealer:

1. Turn on the power switch of the hot melt adhesive host for heating.

2. Set the temperature of the hot melt adhesive on the temperature control table, generally around 175 degrees Celsius in summer and 190 degrees Celsius in winter.

(If the temperature is set in advance, this step can be saved)

3. Put the carton on the conveyor chain and start to adjust the side handwheel to fit the width of the carton.

4. Adjust the side handwheel to a suitable height.

5. Adjust the folding part, turn on the motor, put it in the carton and run it dry (no need to spray glue), adjust the folding steel

The position of the board is fixed.

6. Adjust the photoelectric position of the glue: put in the paper box, turn on the glue switch, set the glue length through the encoder according to the width of the paper box, turn on the machine, and adjust the photoelectric through the starting glue point position on the paper box (also adjustable Gun body position) to make it reach the best starting glue point, and fix the photoelectric.

7. When the temperature of the hot melt adhesive ( the temperature displayed on the touch screen) increases to the setring temperature, activate the buttons on the operation panel and start working.

Notice:

1. This machine can use AC220V civil power supply, and the voltage fluctuation range is ±13%;

2. The flow of the power supply interface should be greater than 15A (ampere);

3. Be sure to connect to a power outlet with a grounding terminal;

4. When repairing, please turn off the power supply;

5. Prevent high temperature burns;

ENGLISH

ENGLISH